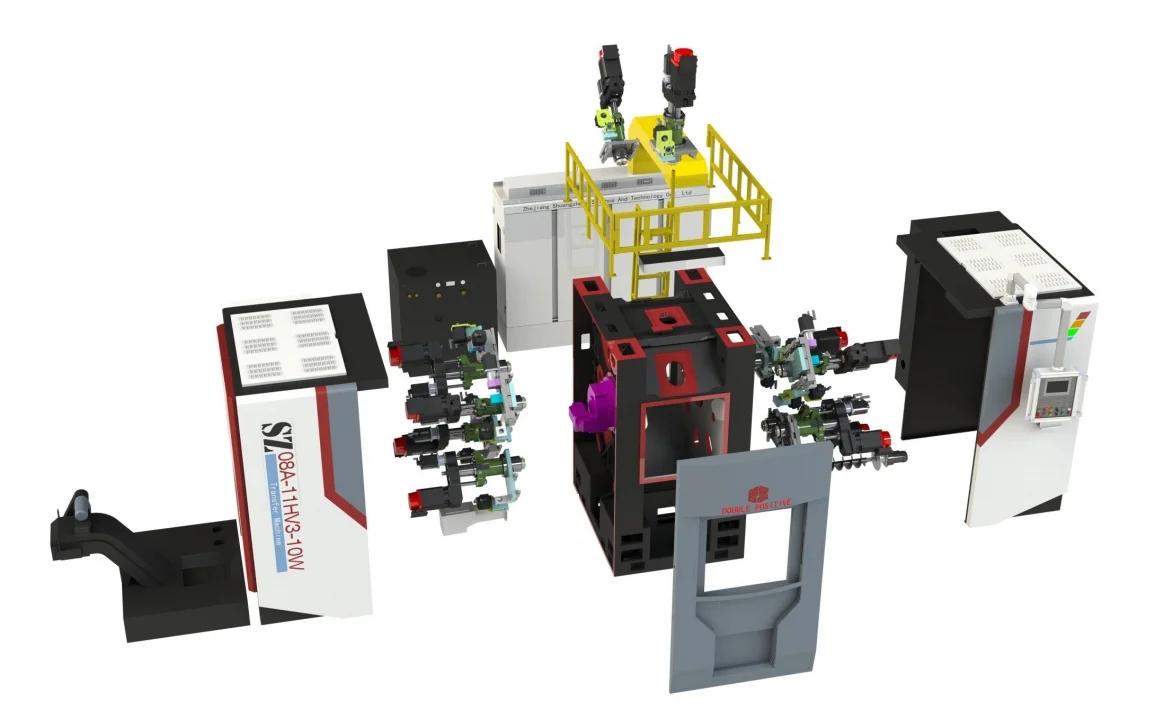

Automatic ball valve assembly machine, is a high performance, high precision, low noise walking type machine tool, is through the CNC system to control the processing program of the automatic processing machine tool. In addition, there are some hydraulic automatic lathes and pneumatic automatic lathes and core automatic lathes, the basic core is that you can automatically process the same product for a long time after setting and adjusting. Especially suitable for copper, aluminum, iron, stainless steel, plastic and other precision parts processing and manufacturing, suitable for instruments, watches, automobiles, motorcycles, bicycles, glasses, stationery, hardware and bathroom, electronic parts, connectors, computers, mobile phones, mechanical and electrical, military and other industries batch processing parts, especially more complex parts.

The control of machine tool is realized by microcomputer programming. Select various program running modes and various running parameters by using knob mode or key setting mode of operation panel. The control system has self-diagnosis and perfect alarm function.

The machine tool has automatic processing, processing speed, complex parts processing molding, processing accuracy is accurate and reliable, the car round, spherical, conical surface, arc surface, step, grooving, embossing, drilling, tapping, die, cutting and other processes, the whole process can be completed by one processing.

ball valve assembly machine customization Talk about the advantages of automatic lathe:

1, the overall bed forward 45 degrees oblique structure layout, good rigidity, convenient chip removal, easy maintenance and adjustment.

2, the use of fully closed open door structure, beautiful appearance, smooth lines, clear external vision, appropriate operating parts.

3. The saddle is equipped with high-precision rolling guide rail, with high positioning accuracy and fast moving speed up to 24M (Z-axis).

4, automatic double head lathe machine using hydraulic clamping wage, safe, stable, reliable.

5, using the form of a row of knives, the workpiece processing time is shorter and the accuracy is stable, and the tool holder can be installed according to customer requirements.

6, the machine adopts double channel, double program control system, can simultaneously process the process of different sizes and shapes at both ends of the structure, and can increase the milling, drilling, tapping and other projects according to customer needs.

7, the main transmission system is configured with frequency conversion drive system, and the servo main drive system can also be configured according to customer needs to achieve stepless speed regulation. Because the main power is transmitted directly to the main shaft by the arc tooth belt, the main shaft has no noise and runs very smoothly.

ball valve assembly machine https://www.zjshuangzheng.com/Rotary-Table-Intelligent-Assembly-Machine.html